Prep Room

Flextraction Laminar Booth LEV

Laminar flow booth to be used in conjunction with the working bench, the unit provides laminar flow across the operator to remove airborne respirable dust The booth uses three stage disposable filtration to remove the dust, finally being diffused back into the working environment via HEPA filtration saving on heat loss.

We offer several finishing options in conjunction with our trusted subcontract partners , which include:

Anodising

- Sulphuric Anodising

- Hard anodising

- Chromic anodising

- Specialist colours

Plating

- Zinc (Bright, Yellow)

- Chemical Black

- Electroless Nickel (Dull, Bright)

- Passivation

Heat Treatments

- Stress Relieving

- Case Hardening

- Nitriding

- Through Hardening

Other subcontract services also include precision grinding, honing & boring deep hole drilling, EDM, Wire Erosion and Broaching .

Above is only an overview of our mainstream subcontract and treatment services we are able to provide our clients. This is not an exhaustive list so please get in touch with a member of our team to discuss any other requirements in detail.

Ultrasonic Cleaning

HS200/2KW Ultrasonic Tank

- Tank Capacity 200 Litres

- Internal Dimensions 700 x 600 x 500 mm

- Internal Basket Dimensions 640 x 560 x 400 mm

- Chemical Multi wash and Draygiene

- Concentration 5 -10% ( add chemical to water — not water to chemical)

- Multi wash (5.25 litres) and Draygiene (0.75 litres) per tank fill

- Temperature 42

2800D Ultrasonic Tank

- Tank Capacity 29.5 Litres

- Internal Dimensions 495 x 292 x 203 mm

- Chemical Ultrasonic cleaner plus

- Concentration 5 -10% ( add chemical to water — not water to chemical)

- Temperature 65

Shot Blasting

Vixen-Fox 25 Shot Blaster

- Tank Capacity 700 x 500 x 500

- Tungsten Carbide nozzle

- Foot pedal control

- Integral extraction high performance Multi-pocket filter

- Powder-coated finish

- Large side door

- Easy pressure conversion

- Fitted with rubber gauntlets

- Fluorescent lighting

Shot blasting is used to prime and clean surfaces, scale or old

coatings to expose clean bare metal ready for subsequent treatment. It also provides an effective method of preparing a surface with a roughened profile which promotes the adhesion of the specialist coatings .

We are equipped to shot blast using media of white aluminium oxide.

For larger components and assemblies it can offer substantial speed and cost savings over other conventional cleaning methods.

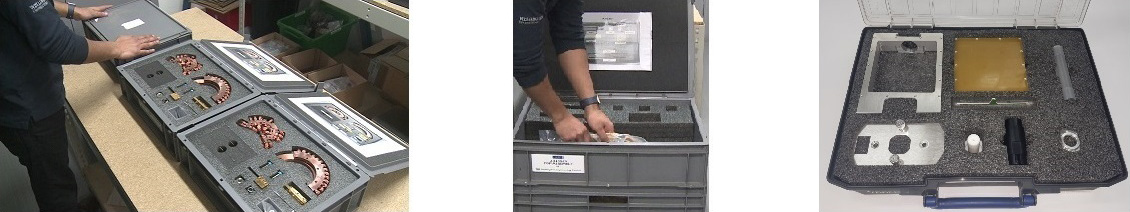

Assembly

With our dedicated assembly room, we can offer you a comprehensive and fast assembly service. We assemble to our customers specifications, either fully assembled products or part assembled. We are also able to offer several joining processes through our subcontract partners. These processes include welding, soldering, Electron beam welding and glueing. Our dedicated working area is perfect for all types of assembly and kit-type work.

KITTING FACILITIES

To offer a world-class combination of supply chain management, manufacturing, inspection and measurement, Wellington Engineering provides a full kitting service to our customers. With components fully protected in secure specialized containers, we can confidently meet your need for an accurate. guaranteed supply of complex and critical items. We often get asked if we can machine and assemble customer projects, this allows the customer to ensure that their components will be fully built upon delivery thus saving them time on assembly.